The most prevalent application of Human-Machine Interface (HMI) is in the context of an industrial process.

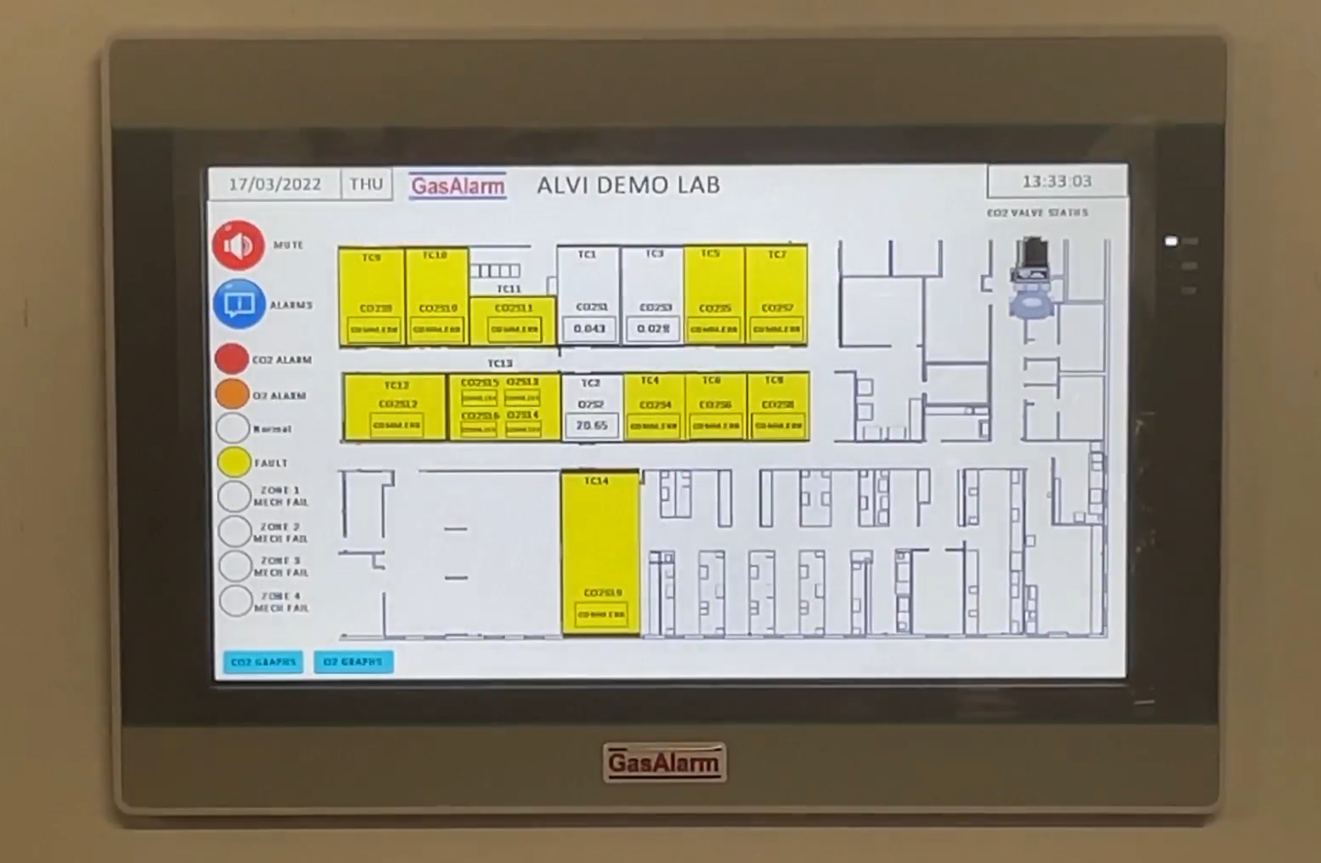

Following is a demo video of our Human-Machine Interface (HMI) for lab users to easily keep an eye on their gas monitoring system and an easy to use user interface.

In this video, we demonstrate how our HMI communicates with a GC06 Gas Controller using Modbus RS-485. It explains how the interface works when an alarm is simulated.

Gas X and Gas Y alarms are shown in various colors to make them clearly distinguishable (say red and amber respectively). Any faults or communication errors are highlighted in an unique color (say yellow). There is a gas detection sensor in each room. When there’s a gas leak, the alarm triggers, and the color of that room changes to the allocated color. This can be altered for low and high level alarms.

The history of the time and date of the sensor that activated the alarm can be found in the alarm sub menu. On the HMI screen, there’s also a mute button that can be used to silence the sounder when any sensor triggers an alarm.

The HMI can generate trends of each installed gas sensors for the past 5 days. When you press the play button, the sensor’s trend will be displayed, and the graph will indicate the gas concentration over time. You can also observe two state solenoid status of a gas on the HMI screen, which can shut off during a high alarm.

We use our SIL2 approved MSR DGC06 gas controller and MSR field sensors for various gases.